Standard Horizon

Rotary Die Cut Machine RD-N4055DMC

Rotary Die Cut Machine RD-N4055DMC

How to Purchase This Item:

How to Purchase This Item:

- Web: Sales Contact Form

- Call: 1-800-343-4231

- Email: sales@midstatelitho.com

- Text: (810) 238-7370

The RD-N4055DMC Rotary Die Cut Machine from Horizon features twin magnetic cylinders, allowing for smooth and efficient die-cutting and creasing/scoring on both sides of the sheet. This versatile machine also offers the ability to perforate, slit, hole punch, and round corner digital and offset printed sheets in one step. With the option to run male and female dies together, the operator can achieve precise and flawless creasing without any cracks or slits.

Rotary Die Cutter

This system features easy change-over and simple operation. A “Repeat Register” function allows multiple-up applications from a single-up die to minimize costs. Ideal for greeting/note cards, playing cards, coasters, door hangers, coupons and tickets, boxes and packaging, stickers (pressure sensitive, gum back, static), bottle and merchandise labels, pocket folders, and unique mailers. Handles complex creasing patterns and light packaging applications with ease.

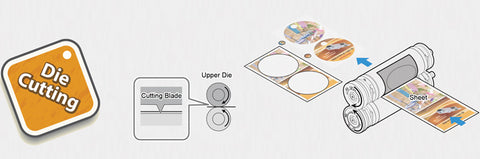

The Horizon rotary die-cutters are designed to meet the growing demand for short-run products. Die-cut, crease, perforation, slit, hole punch and round corner in various substrates up to 0.5 mm / 0.019" (only for die-cutting) thickness for digital and offset printed sheets.

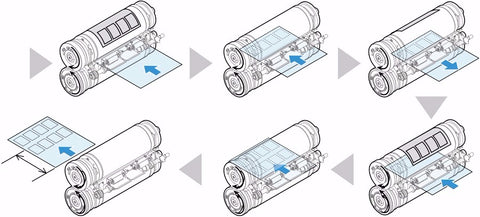

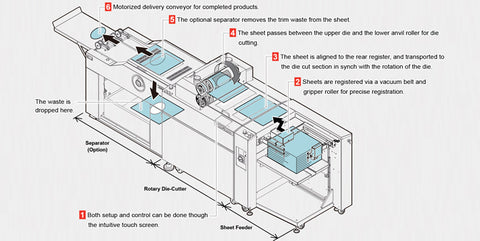

One pass processing means that feeding, die cutting and separating are achieved in one pass at a speed of 6,000 cycles per hour. Uniquely designed to servo motor controlled "Repeat Register" feature allows multiple-up applications from single-up die to minimize die cost. Its simple and easy operation reduces costly labor steps and increases productivity with easy setup and operation versus steel rule or mechanical dies.

Reduce Die Cost with the RD-4055DMC Repeat Register Function

RD-N4055 DMC Product Features

- Rotary Die-Cut System (Max. 400 x 550 mm / 15.74" x 21.65") - Rotary Die-Cutter designed to meet the growing demand for short run product.

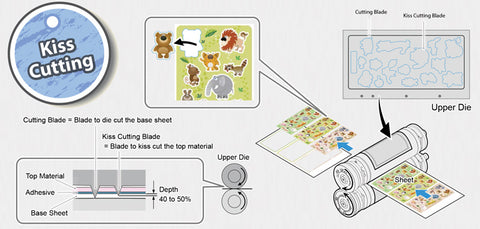

- Flexible Substrate - Die-cut, Crease, Perforation, Slit, Hole punch and round corner in various substrates up to 0.5mm / 0.019" (only for die-cutting) thickness for digital and offset printed sheets.

- One Pass Processing - Feeding, die cutting and separating are achieved in one pass at a speed of 6,000 cycles per hour.

- Save the Cost of Making Die - Uniquely designed servo motor controlled "Repeat Register" feature allows multiple-up applications from single-up die to minimize die cost.

- Simple and Easy Operation - Reduces costly labor steps and increases productivity with easy setup and operation versus steel rule or mechanical dies.

- Deep Pile Feed Capacity - 19.8"

- Auto Size Setting - Up to 14.8" x 20.7" Sheet Size

- Auto Trim Waste Removal with mechanical strip and pneumatic knock down is available with SPC-4055 trim waste separator

RD-N4055 DMC Applications

- Greeting/Note Cards

- Playing Cards

- Coasters

- Place Cards

- Door Hangers

- Coupons & Tickets

- Boxes & packaging

- stickers (Pressure Sensitive, Gum Back, Static)

- Bottle & Merchandise Labels

- Pocket Folders

- Unique Mailers

RD-4055 Sheet Flow Diagram

RD-4055 DMC Technical Specs

| Sheet Feeding System | Vacuum Belt Feed | |

| Sheet Size (Before Processing) | Max. 400 x 550 mm / 15.74" x 21.65" | |

| Min. 200 x 275 mm / 7.8" x 10.8 | ||

|

Finished Size *The size may be limited depending on shape and sheet weight range |

With Separator | Min. 200 x 275 mm / 7.8" x 10.83" |

| Min. 50 x 80 mm / 1.97" x 3.15" | ||

| Without Separator | Max. 376 x 526 mm / 14.8" x 20.7" | |

| Min. Depending on Shape | ||

| Processed Material | Normal Paper, Coated Paper, Cardboard | |

| Material Thickness | 127.9 to 400 gsm Die Cutting : Max. 0.5 mm / 0.019” Creasing : Max. 0.4 mm / 0.015” |

|

| Feeder Pile Height | 500 mm / 19.68" | |

| Upper Cutting Blade Height | 0.6 mm or 0.8 mm / 0.0236" or 0.0315" | |

| Production Speed | 6,000 cycles per hour | |

| Voltage Frequency | Single Phase 200 to 240 V, 50/60 Hz | |

Rotary Die-Cut System RD-N4055 DMC Features