Standard Horizon

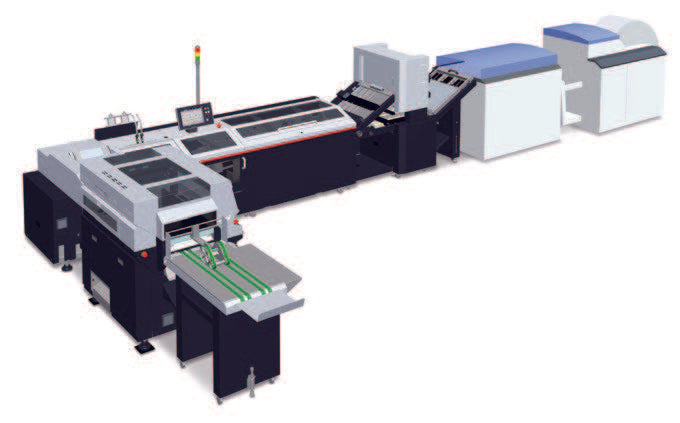

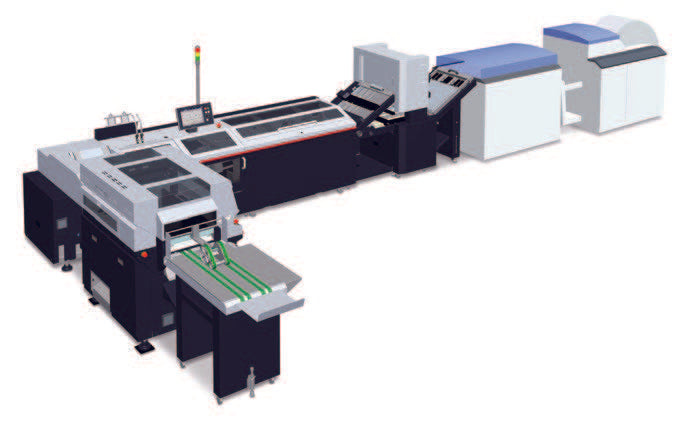

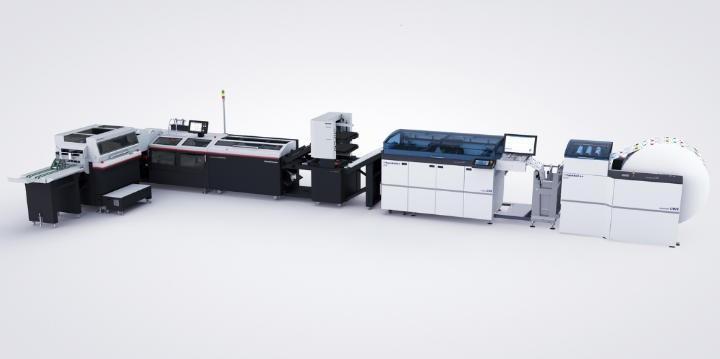

iCE StitchLiner Mark V Continuous Bookletmaking Machine

iCE StitchLiner Mark V Continuous Bookletmaking Machine

How to Purchase This Item:

How to Purchase This Item:

- Web: Sales Contact Form

- Call: 1-800-343-4231

- Email: sales@midstatelitho.com

- Text: (810) 238-7370

Horizon iCE StitchLiner Mark V System Details:

A Bookletmaker Designed For In-Line Operation With Continuous Form Paper

The Horizon iCE StitchLiner is a specialized product that builds upon several generations of StitchLiner and their fantastic reputation. The StitchLiner product line is a high output production machine designed to make saddlestitched books. The Mark V is the model designed for running near-line or in-line with continuous roll paper. Consider the Mark V when utilizing continuous produciton. Continuous web production is special and the Mark V is perfectly designed for the challenge.

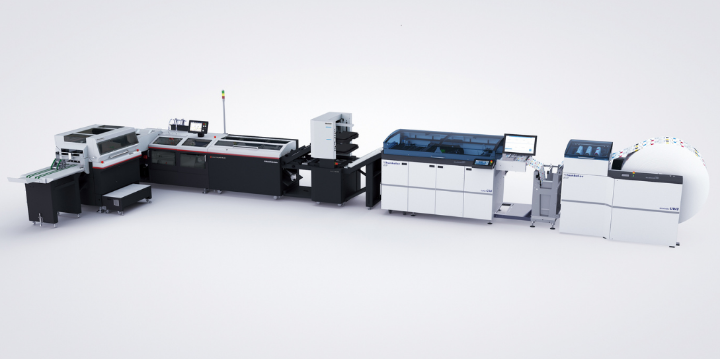

The iCE StitchLiner Mark V Saddlestitcher from Standard Horizon was specially designed to run inline or near-line. This machine is a perfect companion with high-speed, roll-fed digital presses. You can use this automated saddlesticher produces high-quality booklets at speeds of up to 6,000 booklets/hour.

Individual sheets are tightly folded along scoring lines for consistent quality. Even with high page counts or variable page count applications the quality is maintained. Compatible with iCE LiNK, Horizon’s cloud-based workflow management system, the Mark V also supports an optional cover feeder and can handle sheet sizes up 20” x 14” and produce a wide range of booklet sizes including A4 Landscape.

Horizon iCE StitchLiner Mark V Features

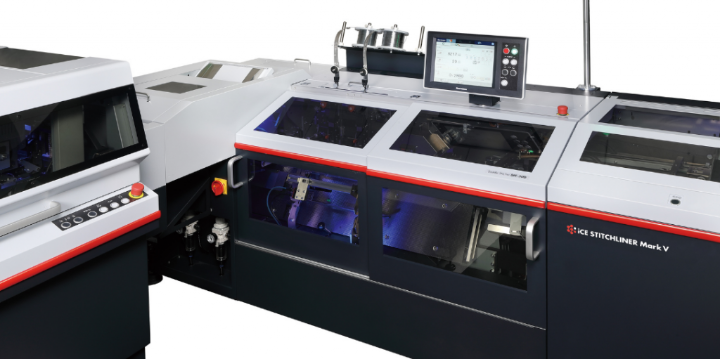

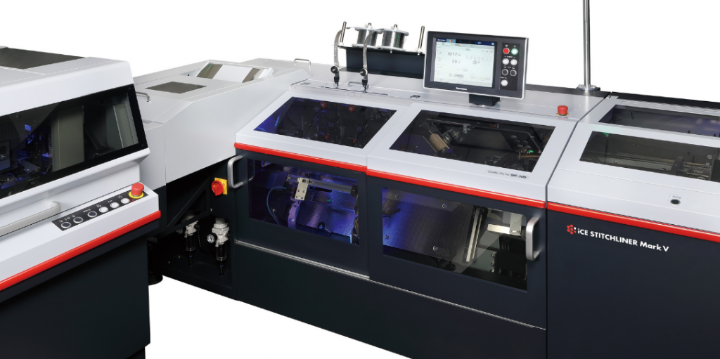

- Individual creasing and scoring: Dual creasing rollers at the in-feed crease every sheet individually before they are folded and accumulated, making tighter, flatter booklets and increasing fold accuracy. Individual sheet creasing and stream folding eliminates the need for sub-setting on higher pager counts. This incerases productivity for booklets to as high as 200 pages.

- Stable sheet transport: A newly designed sheet register allows for more stable transportation of a wider range of paper stocks, including very thin stocks, and a redesign of the accumulating section significantly reduces static build-up between pages, ensuring continuous production.

- No manual touchpoints: Variable production on the Mark V is fully automated, requiring no operator intervention whatsoever. The system can automatically change stitch length, belt and roller pressure, and registration control in the trimmer based on page count.

- Optional cover feeding: The optional dual-bin cover feeder merges covers into the print stream without affecting production speed. Additionally, up to three dual-bin feeders can be combined in one system. This allows for the pre-staging of covers and the option to interpose up to 3 sheets anywhere within the booklet. This feeder can also function as a digital feeder to expand production capabilities.

- Intelligent tracking: The Mark V’s tracking system ensures booklet integrity with optional barcode reading, cover and book block matching, sheet separation verification, and automated rejection of booklets with detected errors.

After installing this equipment and connecting it to the iCE LiNK network the equipment will immediately begin logging status information. Equipment owners can login to ice link to view the current and historical data on their equipment.