Collection: Paper Creasers

Paper Creasing Machines

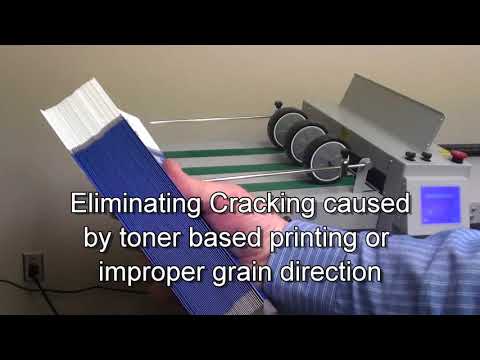

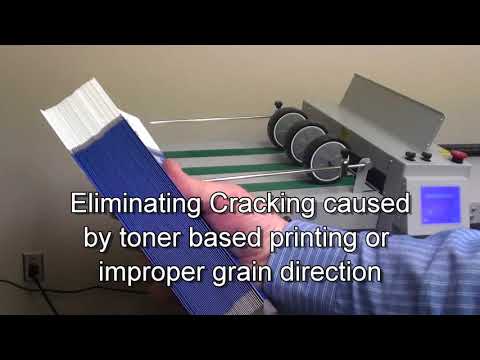

Paper creasing is used to eliminate toner cracking on folded papers. Some coated stocks also tend to crack when folded and creasing is the best way to eliminate that ugly effect. Creasing is different from scoring although both are used to achieve the same effect. Creasing uses a die matrix and creates a small channel to stretch the toner. Scoring uses a roller and drives a channel through the sheet. Scoring works well for offset printing but digital toner often needs creasing instead of scoring.

With the explosion of digital printing comes an ever growing need for creasing. Ask any print manufacturer and cracking along the fold is a major headache. There's nothing worse than creating a beautiful printed piece only to have the final look marred by unsightly cracking. Paper creasing machines eliminate cracking and protect the final look.

Creasing is very different from scoring, even though both techniques are intended to protect a folded edge. For years, with offset printing, scoring was perfect. Ink soaks into stock so although fibers may be cracking when the sheet is folded, the end product still looked great because there was no break in the color. In today's world of digital printing, in which toner lies upon the surface, we have to take a more aggressive approach to preparing the sheet for folding. This is where the paper creasing machine became necessary. Creasing implied the use of a dedicated creasing matrix with a channel and dye. The two sandwich the sheet and create a strong crease in the sheet so that fibers do not break during folding.

Types of Creasing Machines

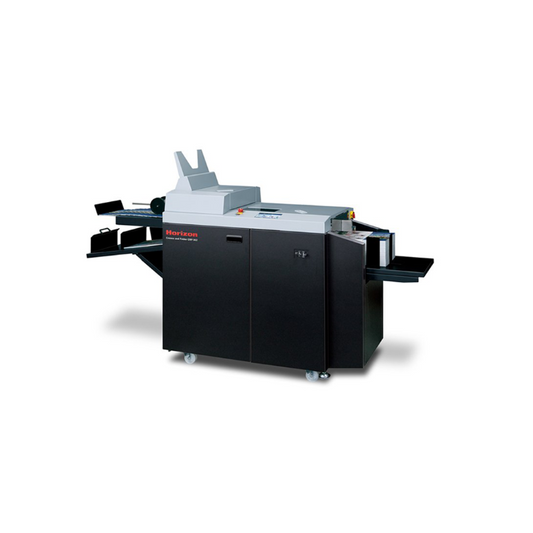

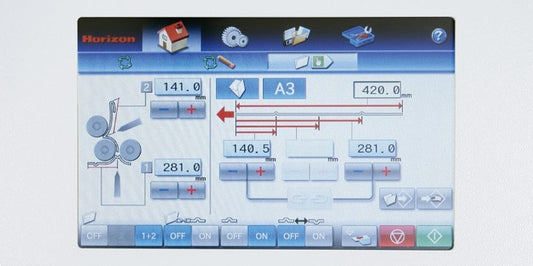

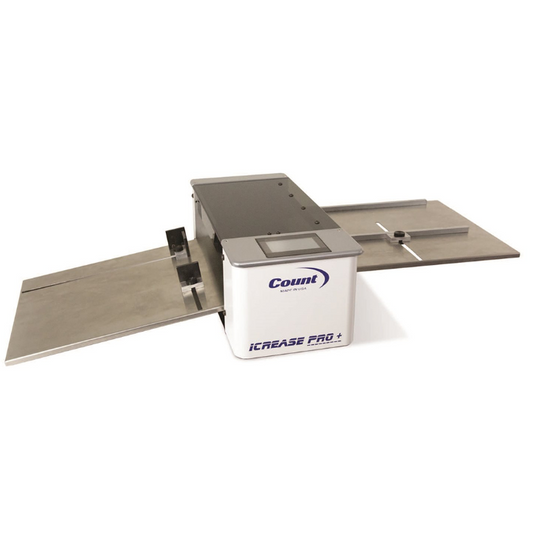

Creasing machines vary quite a bit, most based on duty cycle, but there are other factors as well. Feeding is a big deal; most high end color work is printed on glossy, smooth or coated stocks. Papers of that type require air feeders to separate the stock and then use suction to pull a sheet. Friction feeders are far less expensive but are poorly suited to feed glossy or smooth papers. The drive system for the crease dye is important too, pneumatic drives are fast but very loud and can be inconsistent as air pressure changes. Mechanical cam drives are very strong and consistent, but are traditionally slower than pneumatic drives.

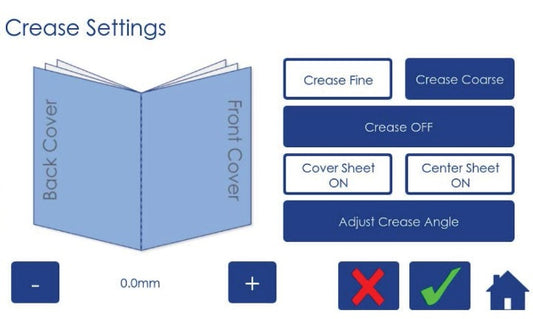

Upcrease vs. downcrease. This one is a hot topic in the industry right now. Some manufacturers insist that up and down creases be performed based on the fold direction. Other manufacturers are having great success with using a single die direction. The truth appears to be that a single die can accomplish the job on the vast majority of paper types. However, there are certainly circumstances where you just can't get the look you need without orienting the crease properly.