Mitsubishi

Mitsubishi TDP-459 and TDP-324 Thermal DigiPlate System

Mitsubishi TDP-459 and TDP-324 Thermal DigiPlate System

How to Purchase This Item:

How to Purchase This Item:

- Web: Sales Contact Form

- Call: 1-800-343-4231

- Email: sales@midstatelitho.com

- Text: (810) 238-7370

Mitsubishi TDP Computer-to-Plate System

TDP-459 and TDP-324e Dual Function CTP and Film Manager Unit

The Mitsubishi TDP-459 and TDP-324 Thermal DigiPlate system offers an affordable way for businesses to go green while also increasing productivity. This 2-up, dual function CTP system is perfect for printers that primarily handle one or two color jobs and are interested in an environmentally friendly upgrade from analog and electrostatic plates.

With a resolution of 1200 dpi, high-speed production capabilities, and the ability to output plates or film, the Thermal DigiPlater is a great fit for high-volume environments seeking a productive and eco-friendly solution. The unit is highly automated and requires minimal training to operate, allowing for quick production of clean, press-ready plates or high-density film output.

By loading it with Mitsubishi's thermal plate or film material, the Thermal DigiPlater essentially runs itself. It can receive 1-bit TIFF files from a RIP to the TDP Controller, and plates are imaged, cut to size, and ready for press in under a minute. Film can

-

Features of the Eco-Friendly Thermal DigiPlate TDP-459E/324E Platesetter:

- Thermal inline head technology

- Optimized for 2-up format with a resolution of 1200 dpi/120 lpi

- No chemicals, toner or ink ribbon are necessary, providing easy maintenance

- High speed - 75 plates/hr

-

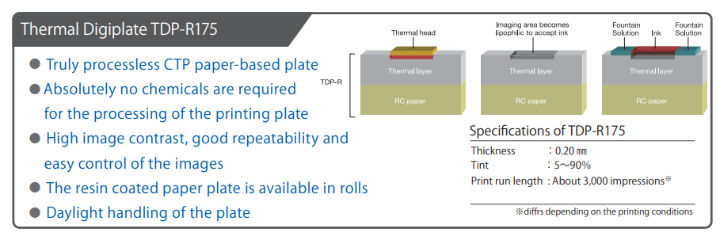

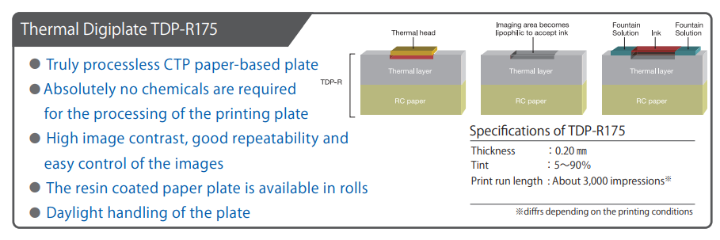

Features of the Eco-Friendly Thermal DigiPlate TDP-R175 Plates:

- Truly processless CTP paper-based plate

- Absolutely no chemicals are required for the processing of the printing plates

- High image contrast, good repeat-ability and easy control of the images

- The resin coated paper plate is available in 246' rolls

-

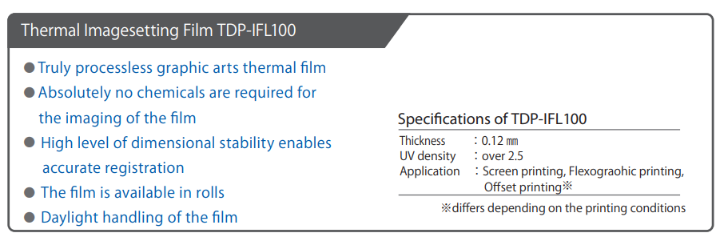

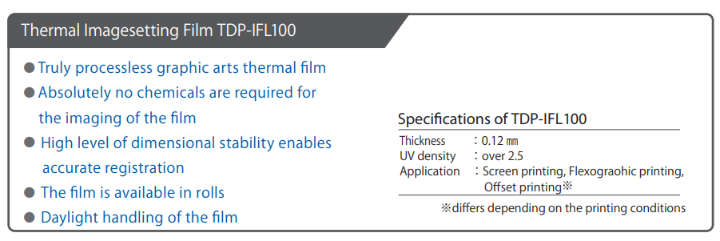

Features of the Eco-Friendly Graphic Arts Film TFP-100:

- Truly prcoessless clear graphic arts thermal film

- Absolutely no chemicals are required for the imaging of the film

- High level of dimensional stability enables accurate registration

- DMAX>4 and film available in 200' rolls

Technical Specifications:

| Film Type | Thermal-sensitive, graphic arts film |

| Film Gauge | 5 mil (0.12mm) |

| Film Format | >4 |

| UV | >5 |

| Plate Technology | Thermal-sensitive CTP resin-coated paper-base |

| Plate Gauge/Base | 8 mil (0.20mm) paper plate (TDP-R175) |

| Plate Format |

TDP-459:

TDP-324:

|

| Print Run Length* | Up to 5,000 impressions *under suitable printing conditions |

| Printing Performance | Performs with regular fountain solution and ink |

| Machine Controller | TDP controller software accepts 1-bit TIFF. RIP options : TDP-1300 RIP v9.x (Harlequin) includes bonus SDP-Smart Tools workflow management software |

| Processless | No processor; no chemistry, no ribbons, no toner, no ink |

| Punch | N/A |

| Material Supply | 1 magazine - roll material; Thermal DigiPlate, Spec 725; 246' roll lengths ; TFP-100 thermal film, 200' roll length |

| Light Imaging/Source | In-line thermal head with patented thermal fusing technology |

| Resolution | 1200 dpi |

| Recording Speed | 75 plates/hr @1200 dpi; film speed will vary based on image size and film output (negative or positive) |

| Screen Ruling | 120 lpi |

| Tint | 5% to 90% |

| Power Requirements | AC100/220V Auto sensing |

| Environment | 50-70% relative humidity |

| Temperature | 77 ± 9°F (25 ± 5°C) |

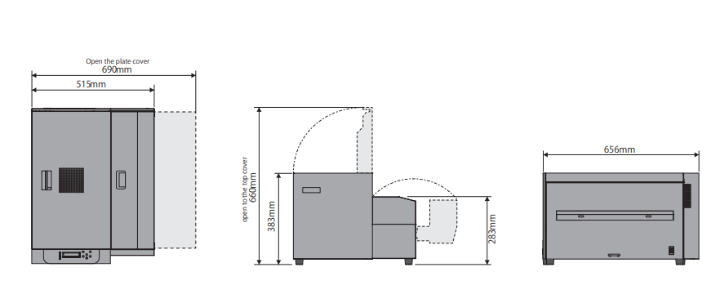

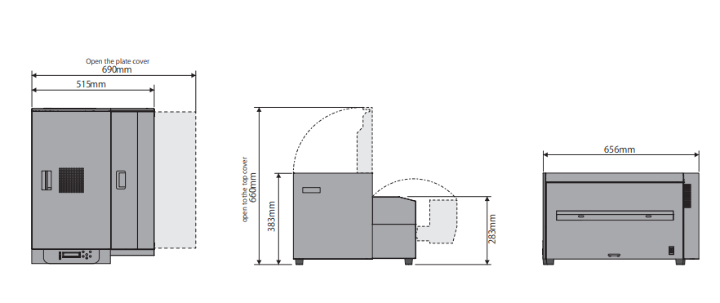

| Dimensions (W x D x H) | 20.2" x 26" x 15" (515mm x 663mm x 383mm) |

The Thermal DigiPlater is a fully automated CTP system. It requires minimal training to operate and minimal time to produce press-ready plates. You simply load it with a roll of Thermal DigiPlate TDP-R175 and the Thermal DigiPlater essentially runs itself. You can send 1-bit Tiff files from a RIP to the TDP Controller. Plates are imaged, cut to size and ready for press in less than a minute. Conventional platemaking steps like exposing and processing film, paste-up, stripping and plate burning are suddenly obsolete, as is chemical processing. That saves you time, money and materials.