Standard Horizon

Standard Horizon SmartSlitter Sheet Cutter & Creaser

Standard Horizon SmartSlitter Sheet Cutter & Creaser

How to Purchase This Item:

How to Purchase This Item:

- Web: Sales Contact Form

- Call: 1-800-343-4231

- Email: sales@midstatelitho.com

- Text: (810) 238-7370

SmartSlitter by Standard Horizon Product Details:

Standard Horizon introduces an all-in-one smart sheet processing system that can slit, gutter cut, edge trim, cross-cut, perforate, and crease all in one pass. Print mark registration adjusts for digital print image shift from sheet to sheet. Simple operation and easy job set-up via barcode. The SmartSlitter is ideal for greeting cards, table tents, invitations, and business cards. Skip perforation feature for tickets, coupons, and reply cards.

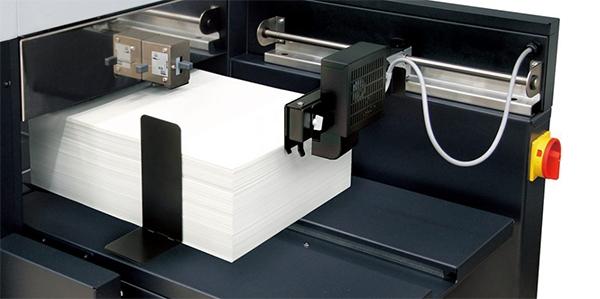

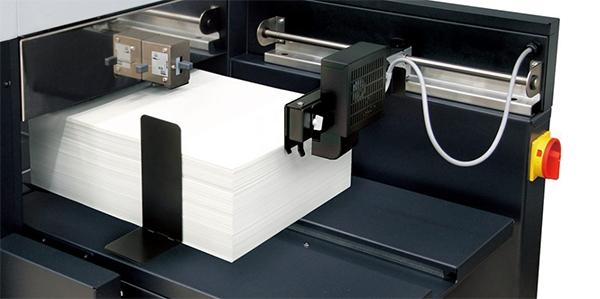

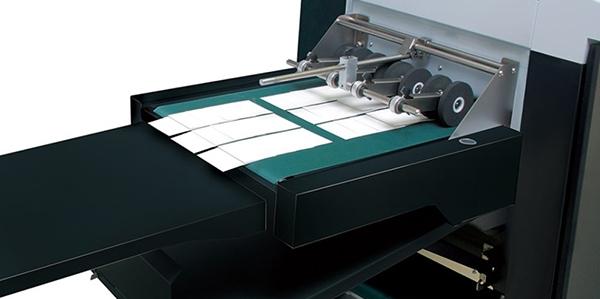

The SmartSlitter offers a host of innovative features for easy operation and production flexibility. Perforation, creasing, and slitting can be performed in both horizontal and vertical directions in the same pass. The system can deliver multiple-up greeting cards with or without creasing. For accordion fold applications or perfect bound books, up and down creasing can also be performed in one pass. Produce standard size business cards printed 21-up on a sheet and process to receding stacker for easy handling. The system accepts sheets up to 14.33" x 26.37" and can deliver finished sheets just under 2" x 2".

Product Features & Benefits:

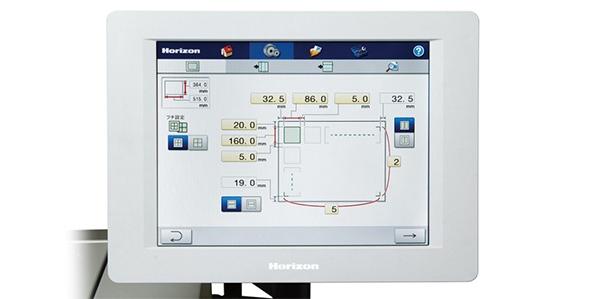

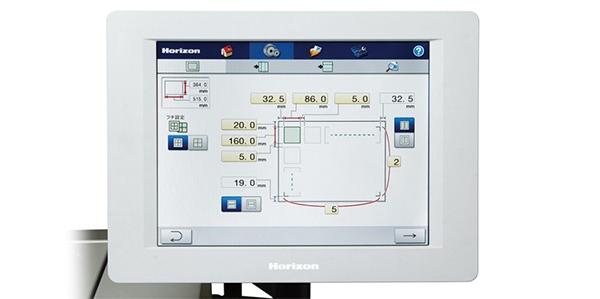

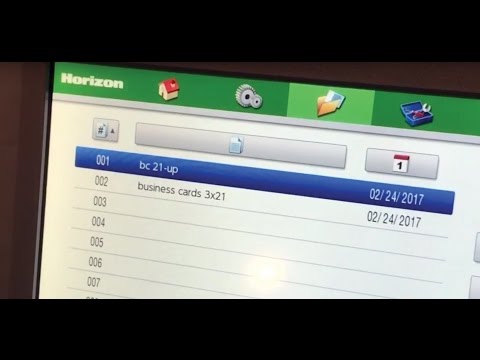

- Easy-to-use touchscreen: The color touch screen features a simple user interface for easy operation including job set-up via barcode.

- Mark registration: Print mark registration adjusts for digital print image shift from sheet to sheet.

- Sheet range: The system accepts sheets up to 14.33″ x 26.37″ and can deliver finished sheets just under 2″ x 2″.

- Business card processing: Standard size business cards can be printed 21-up on a sheet and processed to a receding stacker for easy handling.

- Perforation options: Perforation and creasing can be performed in both horizontal and vertical directions in the same pass. The skip perforation feature can produce T- and L-perfs – ideal for coupons, tickets, and business reply cards.

- Creasing options: The system can deliver multiple up greeting cards with or without creasing, table tents, invitations, and more with both matrix and rotary creasing. For accordion fold applications or perfect bound books, up and down creasing can also be performed in one pass.

Equipment Specifications:

| Installation Type | Floor Model |

| Sheet Feeding System | Max. 370 x 670 mm / 14.33" x 26.37" |

| Min. 210 x 210 mm / 8.27" x 8.27" | |

| Sheet Weight Range | Normal Paper: 81.4 to 350 gsm / 20 lb. bond to 17 pt. cover |

| Coated Paper: 70 lb. text to 17 pt. cover | |

| (Rotary Perforate / PRF-36) | |

| Normal Paper: 81.4 to 209 gsm / 20 lb. bond to 10 pt. cover | |

| Coated Paper: 128 to 256 gsm / 80 lb. text to 11 pt. cover | |

| Feeder Pile Height | 150 mm / 5.9" |

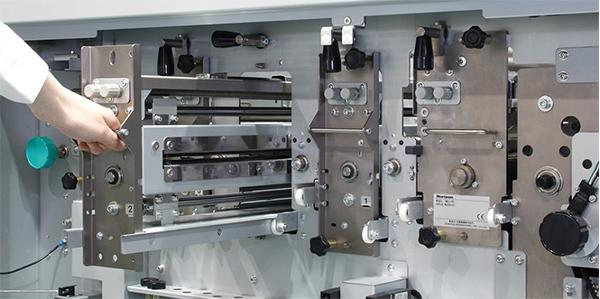

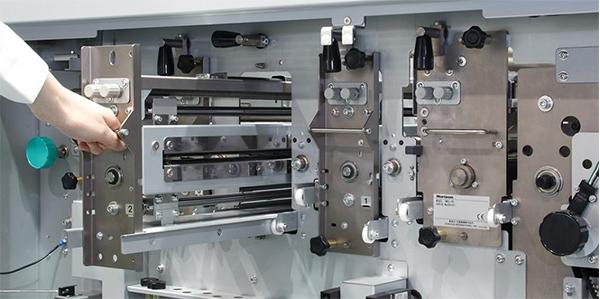

| Impact Creasing Mechanism | One set of positive and negative |

| Number of Impact Creasing Lines | 20 creasing lines |

| Production Speed | 55 Sheets/Min. |

| (A4 / 8.5" x 11" short-edge feeding, two cuts, one creasing line) | |

| 48 Sheets/Min. (JLS B3 / 14.33" x 20.27" short-edge feeding, two cuts, one creasing line) | |

| Voltage/Frequency | Single Phase 200 to 240 V, 50 / 60 Hz |

| Without CE: Single Phase 200 to 240 V, 50 / 60 Hz | |

| For UL: Single Phase 208 to 220 V, 50 / 60 Hz |

Equipment specifications and features are subject to change without notice. Please contact us for additional information at 810.238.7370.

Available Options| Rotary Perforation Cassette SMSL-PR |

Perforation is performed in the direction of paper feeding. Two rotary perforation units are equipped. |

| Rotary Creasing Cassette SMSL-CR |

Creasing is performed in the direction of paper feeding. Two rotary creasing units are equipped. |

| Impact Perforation Unit PF-36 |

Perforation lines can be made in the width direction by replacing the first creasing unit with the optional PRF-36. |

| Impact Creasing Unit |

Different widths of creasing lines are available using this unit: Standard width is 0.8mm/0.031"

|

| Camera Device SMSL-CA |

This camera reads the print registration mark or barcode to adjust the cutting, perforating and creasing position according to image position. This camera is also used to read the barcode for automatic job set-up. |

| Conveyor SMSL-CV |

Motor driven conveyor. The finished product can be delivered on the motor driven conveyor. Batch and pausing can be performed by the pre-set number set at the touch screen. |

| Stacker SMSL-ST |

Stacker delivery device. Suitable to receive small products such as business cards or greeting cards. Stacker tray height descends automatically. It can stack up to 90mm (3.54") height. |

Equipment features and specifications are subject to change without notice. Please contact us for additional information at 810.238.7370.